cross section analysis

Cross-Sectioning:

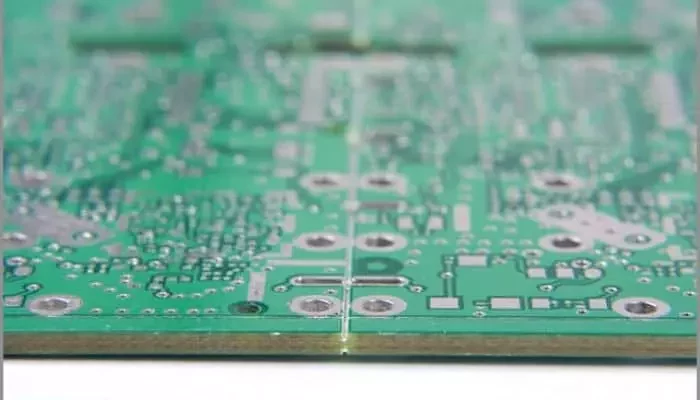

cross section analysis or micro sectioning analysis is a destructive failure analysis technique to expose a plane of interest in a specimen such as a die cross-section, connector cross-section, solder ball cross-section, plated materials cross-section, capacitor cross-section, resistor cross-section, metal cross-section, PCB Cross Section analysis, or any other device for further analysis or inspection.

Sample preparation consists of cleaning, mounting, and encapsulation of the specimen in polyester or epoxy resin. These steps provide support, stability, and protection. Sometimes, a sample is sawed to reduce its size prior to encapsulation. This is usually done to fit the specimen perfectly into the mold, as well as to reduce the grinding needed during actual sectioning.

The process of micro-sectioning begins with sample preparation. The area of interest is identified and marked carefully. Parts may need to be removed from the surrounding area of interest. This is followed by the mounting, sawing, grinding, polishing, and staining of the specimen and finally recording and analysis of the findings based on the images. At the completion of these processes, the plane of interest has been made ready for high-power optical microscopy or SEM analysis.

What equipment are typically used in a Cross-Section?

- Diamond saw to cut the specimen near the interest area.

- Grinder to gradually grind it down until we meet the desired plane of interest.

- Polisher - This task is performed with silicon carbide paper, colloidal silica, and aluminum powder to achieve a smooth and clean surface.

- Metallography – An optical microscope with a zoom up to 1000X is used to analyze the cross-section plane of the specimen.

- Scanning Electron Microscope (SEM) – It is a focused beam of electrons to create images of the cross-section surfaces. These images are used to identify anomalies in the sample.

Cross-section and SEM analysis of a semiconductor die can identify the internal structure of the sample during a failure analysis or reverse engineering.

Cross-section analysis is just one of many failure analysis techniques used by the IC Failure Analysis Lab. The analysis is a destructive process and it provides an in-depth understanding of anomalies within a specimen. IC Failure Analysis Lab has over 15 years of experience performing failure analysis on semiconductors, passive components, and PCBs. Contact us for more information and a free quote.

IC Failure Analysis Lab uses the following four different cross-sectioning methods to serve its customer’s needs and requirements.

Mechanical cross-sectioning is usually a process to expose a plane of interest in a uniform specimen such as IC, PCBA, LED, Metal, Glass… for further inspection. The process consists of diamond sawing, grinding, polishing, and staining the sample until the plane of interest is ready for optical or scanning electron microscopy inspection. The mechanical method of cross sectioning requires the encapsulation of the specimen in epoxy / resin to give it stability, support, and protection.

The DB-FIB method is effective for cross-section specimen preparation of the micro area and thin-film specimen preparation, however, it is not effective for the preparation of a wide surface area of a specimen. FIB is mainly used to create very precise cross-sections of a sample for subsequent imaging via SEM, STEM, or TEM or to perform circuit modification.

The P-FIB and DB-FIB methods differ from each other in their ion sources and etching speed. P-FIB uses Xe ion plasma and etches at higher speed; therefore it can run over larger areas (greater than 100um). P-FIB probe current is 1.3 μA. DB-FIB probe current is 65nA. P-FIB is capable of running over large areas at 20 times faster than DB-FIB.

The CP is chiefly used on a specimen with different material hardness, void, or softness… The cross-section plane can be larger than the FIB plane. The specimen size is much smaller than mechanical preparation. The maximum size of the specimen is 11(W) 10mm (D) 2mm (H).

optical microscopy failure analysis • ic decapsulation service • Counterfeit Component Authenticity • Parallel Lapping • Energy Dispersive X-Ray Spectroscopy • Focused Ion Beam • i-v curve analysis • Photoemission microscopy failure analysis • Scanning Acoustic Microscopy • electron microscope services • Secondary Ion Mass Spectrometry • IC X-Ray services