IC Failure Analysis Lab

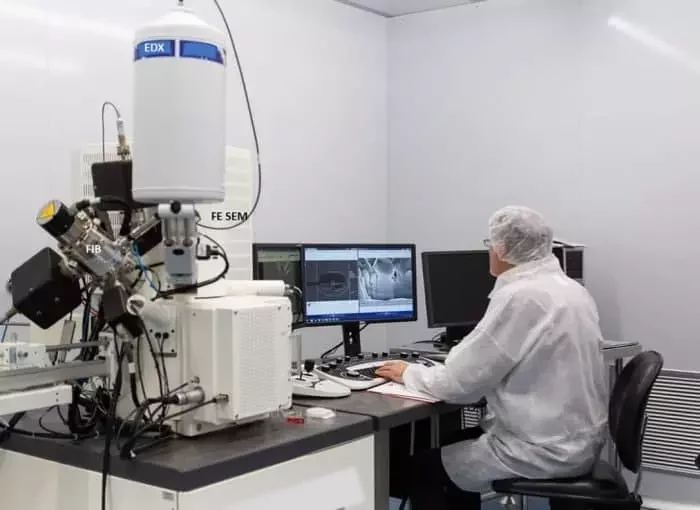

IC Failure Analysis Lab is a privately held company located in Orange County, California. IC Failure Analysis Lab’s personnel have decades of collective experience in micro analysis and process analysis. Hence, these experiences have enabled us to bring high quality and low cost Failure Analysis, Microsurgery, and Reliability testing services in semiconductors, microelectronics, automotive, medical devices, telecommunications, reverse engineering, electronics, aerospace, military, and computers to our customers. Our state-of-the-art equipment and breadth of skilled workers are unmatched in America. Our turnkey services can save up to 45% of your current FA and Reliability testing costs and reduce your cycle time.

Why do you need IC Failure Analysis Lab’s Services?

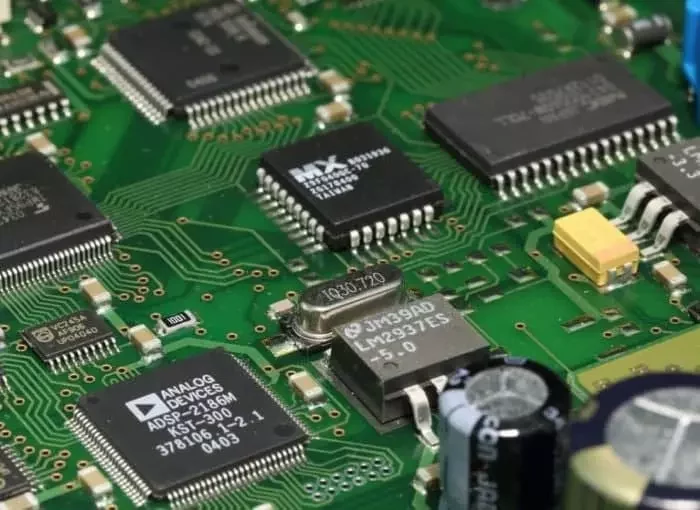

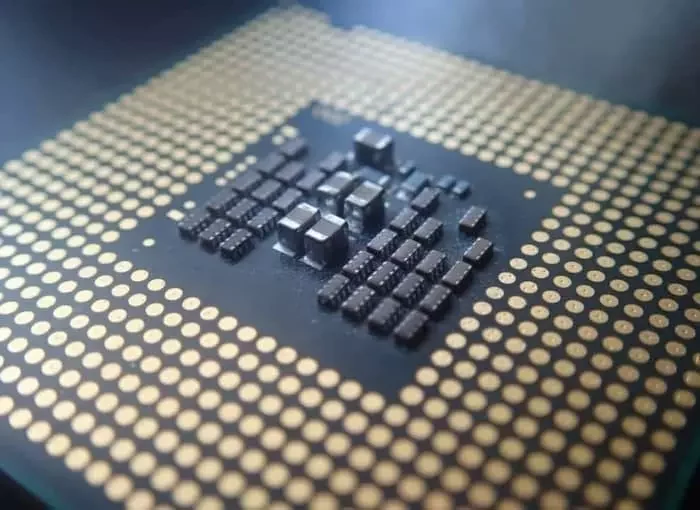

Electronics and technology have fulfilled our daily life today. Electronic products manufactured with advanced, reliable, and complex integrated circuits (ICs) and components. A component failure inside a product will cost the manufacturing companies millions of dollars in repairs cost, lower productivity, and lower confidence level among the end-users. Our failure analysis and reliability testing services will identify the root cause of failures upstream in the manufacturing processes and eliminate unnecessary costs and downtime in production lines.

IC Failure Analysis Lab’s experienced analysts and state-of-the-art equipment will eliminate unnecessary repair and downtime costs by providing on-time and accurate failure analysis reports.

IC FAILURE ANALYSIS SERVICES

IC Failure Analysis Lab

Are you looking for a reputable and independent Failure Analysis Lab to identify the root cause of failures in your electronic products? Look no further; the IC Failure Analysis Lab is a one-stop full-house lab. The IC Failure Analysis Laboratory provides the most accurate, fastest, and lowest cost semiconductor failure analysis services. Our lab keeps the customers informed by providing interim reports throughout the analysis.

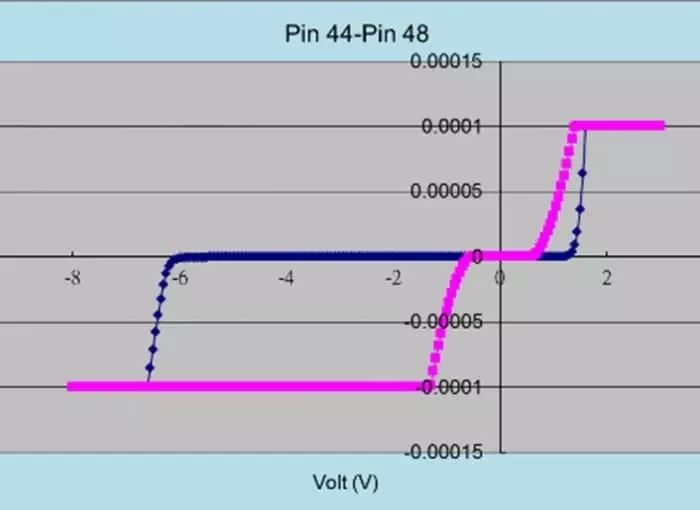

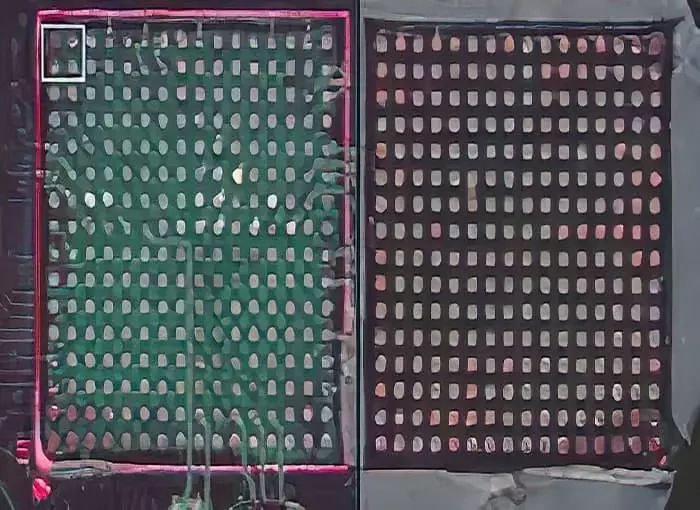

The following technics are non-destructive analyses that identify obvious anomalies in any electronics components. We use Optical microscopes (OM), 2D or 3D X-Ray, Scanning Acoustic Microscopy (SAM), and I-V Curve Tracer to access the condition of each sample.

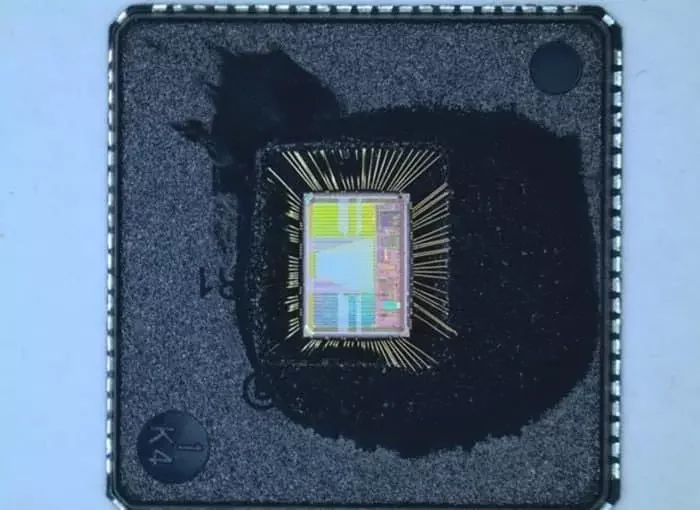

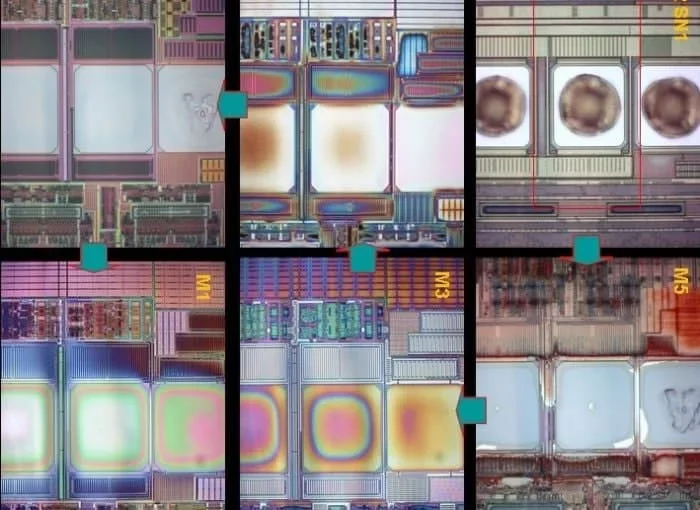

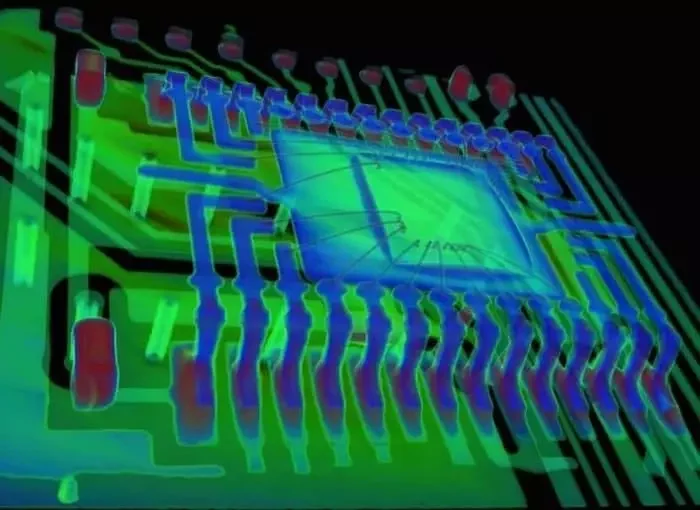

By exposing the internal circuits of a sample, our analysts investigate customer-reported failures (s). The analyst decapsulates the sample and uses an OBRICH/EMMI photoemission microscope to find the emission sites (hot spots) on the die surface.

We use multiple equipment and techniques to find the root cause of the reported failure. The most common methods are Delayering / Parallel Lapping, Scanning Electron Microscopy (SEM), Cross Section, Energy-Dispersive X-Ray Spectroscopy (EDX), Focused Ion Beam (FIB), Secondary Ion Mass Spectrometry (SIMS), etc.

PCB Failure Analysis

IC Failure Analysis

IC / Package / PCB Cost Analysis

IC / Package / PCB Reverse Engineering

Optical Profiler (OP)

SCM (Scanning Capacitance Microscopy)

TEM (Transmission Electron Microscopy)

Sample Reports

Our Clients

About Us

IC Failure Analysis Lab is a privately held company located in Orange County, California.

IC Failure Analysis Lab Services’ personnel have decades of collective experience in micro analysis and process analysis. These experiences have enabled us to bring high quality and low cost Failure Analysis, Microsurgery, and Reliability testing services to our customers. Our state-of-the-art equipment and breadth of skilled workers is unmatched in America and Asia.

IC Failure Analysis Lab was established with a help of two industry veterans in 2008 to help our clients to save money in their Failure Analysis and Reliability testing services by providing fast and high quality services at lower prices.

Our turnkey services can save up to 45% of your current FA and Reliability testing costs.

Confidentiality and Security

All work undertaken is handled with the strictest confidence. A written declaration of non-disclosure is part of our standard Terms and Conditions.

Our Promise

- We promise to provide the best services and do our best to identify the root cause of failure.

- We promise to keep you up to date with on-going status report.

- We promise to offer you the best and lowest cost per analysis.

- We promise to offer you the most competitive price. If our quote is not within your budget, please let us know and we will work with you.

Our Clients

Industries

Aerospace Devices

Automotive Devices

Internet of Things

Medical Devices

Microelectronics

Reverse Engineering

Semiconductors

Telecommunications

FAQ

First and foremost, clearly serialize your parts and identify your reference part. Secure and place them in an ESD safe box before shipment to us. We recommend FedEx, UPS or any carrier with tracking number.

Yes, we accept jobs from every county. We have customers in Europe, Canada, Isreal…

Electrical failure can be either functional or parametric. Functional failure refers to the inability of a device to perform its intended function. Parametric failure refers to the inability of a device to meet the electrical specifications for a measurable characteristic (such as leakage current) that does not directly pertain to functionality. Thus, a parametric failure may be present even if the device is still functional or able to perform its intended function.

Contact Us

Request a Quote

General Questions :

Contact Number :

Address :

Bill & Ship To: 27555 Homestead Rd – Laguna Niguel, CA 92677-6602

Lab (New Address): 3506 W Lake Center Dr, Suite D – Santa Ana, CA 92704