Scanning Electron Microscope (SEM) Services

Scanning Electron Microscope (SEM) Services

Scanning Electron Microscope (SEM) provides NP morphology and estimates the sample composition through Energy Dispersive X-Ray Spectroscopy (EDS). IC Scanning Electron Microscopy Machine produces images by scanning a sample with a focused pin of electrons. Scientists in various fields use scanning electron microscopy to learn more about the composition and topography of manufactured and naturally occurring materials.

Industries that use microscopic components to create their products often use scanning microscopy to examine small details like fine filament and thin films. Scanning electron microscopy can pinpoint the problem and help find a solution if a problem is observed at a microscopic level. Scanning

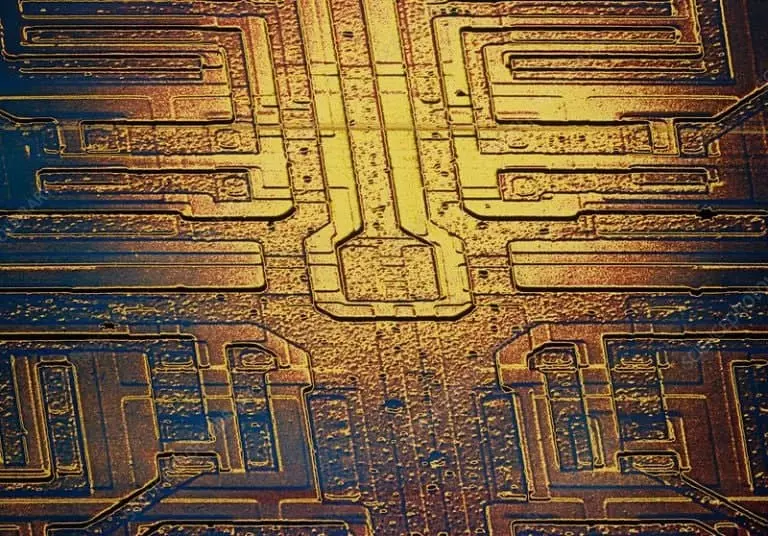

The below images are samples of SEM pictures :

IC SEM services are used to inspect topographies and composition of materials with a magnification range that encompasses optical microscopy and extends it to the nano-scale. ICFA Lab offers a variety of advanced SEMs to meet customer requirements and application needs.

The electron beam is generally scanned in a raster scan pattern, and the beam’s position is combined with the detected signal to produce an image. Specimens can be observed in high vacuum, low vacuum, wet conditions (in environmental SEM), and at a wide range of cryogenic or elevated temperatures.

Contact us for more information about IC Scanning Electron Microscope (SEM) Services

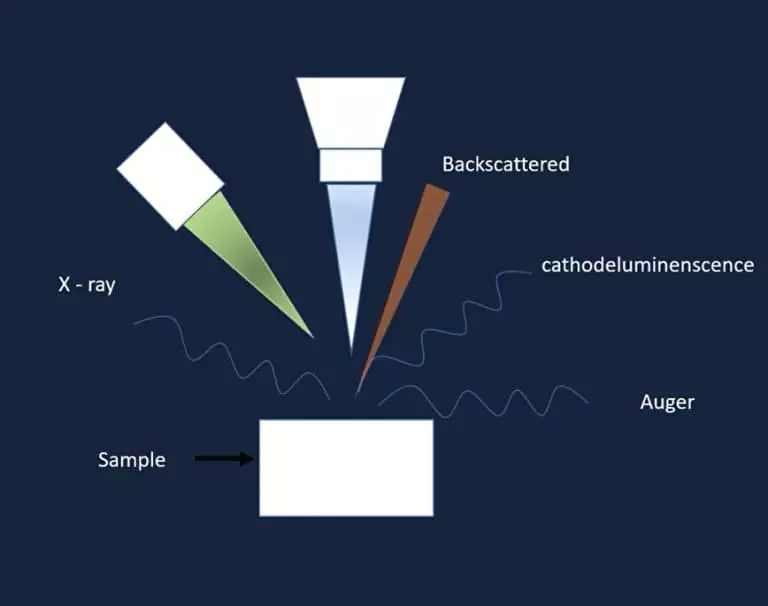

The most common SEM mode detects secondary electrons emitted by atoms excited by the electron beam. The number of secondary electrons that can be detected depends on the angle at which the beam meets the surface of the specimen.

How does IC Scanning Electron Microscope work?

The operation of SEM can be divided into two parts:

- Principle function of scanning electron microscopy.

- Mechanism of a scanning electron microscope.

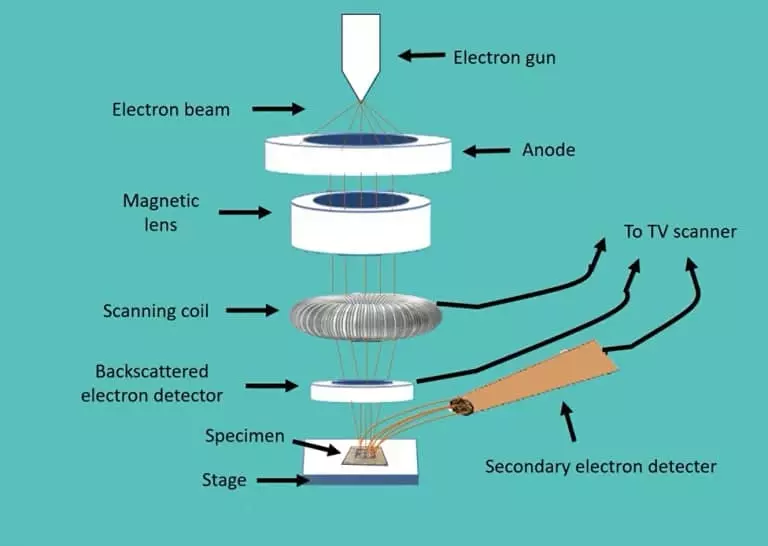

The below picture depicts the principle of scanning electron microscopy. It includes an Electron Gun, Electron Beam, Anode, Magnetic Lens, Scanning Coil, Backscattered Electron Detector, Specimen, Stage, and a Secondary Electron Detector.

Principle operation of scanning electron microscopy

The fundamental of scanning electron microscopy is a high-energy electron source positioned above a series of conditioned lenses and apparatuses which focus the electron into a beam. The position of this beam is attached by a set of deflection or scanning cards before the final test operation. The sample is placed in the path of the electron beam, which is continuously flattened into a raster scanning pattern by deflection cards.

Mechanism of scanning electron microscope

Scanning electron microscopy can subsequently be used for imaging the elemental composition of a sample surface and determining topographical sample features with a significant increase with solving power. Scanning electron microscopy can generate 3D chemical surface maps of a sample with a magnifying capacity of 50 thousand volts.

Scanning Electron Microscope Advantages

There are some benefits of using an SEM for material characterization and failure analysis.

- ICFA SEM Services provide digital image resolution as low as 15 nanometers

- ICFA Scanning Electron Microscope Services used in the characterization of a specimen such as coating thicknesses, grain size, determinations, and particle sizing

- Scanning Electron Microscope or SEM can be used to examine product defects.

Scanning Electron Microscope Disadvantages

There are also some disadvantages to SEM:

- Scanning Electron Microscope equipment is expensive, large, and must be housed in a lab environment.

- SEMs required keeping a steady voltage, currents to electromagnetic coils

- SEMs generates a small amount of radiation

IC Failure Analysis Lab can provide you a high-quality IC SEM (Scanning Electron Microscope) services with a proper mode and accurate reports with high-resolution pictures of your components.

Request a free quote for SEM services and get a consultation from our experts.

i-v curve analysis • ic decapsulation service • Counterfeit Component Authenticity • Cross Section Analysis • Parallel Lapping • Energy Dispersive X-Ray Spectroscopy • Focused Ion Beam • optical microscopy failure analysis • Photoemission microscopy failure analysis • Scanning Acoustic Microscopy • Secondary Ion Mass Spectrometry • IC X-Ray services